Contrary to popular belief, the motor car was not necessarily invented by anyone, it was merely an evolution of its forefathers the horse and cart, of which the latter which was then successfully propelled by steam alone, and the tricycle. These were then commonly referred to as horseless carriages

In 1860, Belgian inventor Etienne Lenoir built the first practical example of the internal combustion engine.

|

| Etienne Lenoir 1822-1900 and his famous engine |

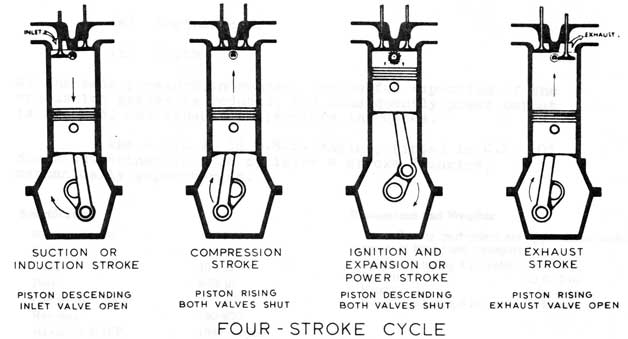

Throughout the next two decades, numerous experiments were carried out to bring the concept of self-propulsion to light. A breakthrough came in 1874 when Austrian inventor Siegfried Markus built a small cart powered by a four-stroke engine which was itself then successfully installed by German engineer Count Nicholas Otto in 1876 hence the name “Otto Cycle” which is still used to describe the working principles of the four-stroke engine today. Before this, vehicles ran on steam.

|

| An early Otto engine |

Steam engines would still be widely used on trains in Britain until the mid 1960’s. The main difference of these engines is that steam engines rely on external combustion, simply meaning that the fuel is burnt outside of the cylinders and internal combustion engines burnt their compressed mixture of air and then coal gas inside their cylinders. But once petrol was used instead of coal gas, it could then be made mobile and efficiency improved greatly. The birth of the motor car was soon to follow.

The persons responsible for the motor car today are those who first made it work. Gottlieb Daimler (1834-1900) and Karl Benz (1844-1929) (both of whom are pictured above respectively) the former having worked for Otto and then setting up alone in 1882 where he was joined by fellow Otto graduate Wilhelm Maybach. Together, they came up with the Daimler-Maybach engine which could run at speeds up to 900 rpm, some 700 rpm more than the engines of Otto. Daimler’s engines evolved constantly and swiftly and his single-cylinder engine soon evolved to a twin-cylinder vee engine fuelled by a carburettor of Maybach’s design using a hot-tube ignition system in which fuel was ignited by a small platinum pipe kept red-hot by a burner.

Benz also developed a four-stroke engine which used a singer-cylinder arrangement producing ¾ hp. This engine used the innovation of spark ignition in favour of hot-tube, and in 1885, this engine would be used to power the car he designed and carried his name, which was the first of its type having three wheels, two seats and was capable of 8 mph. This engine featured the mushroom shaped poppet valve and water-cooling, both of which survive today! The water did however not circulate, it was stored in a tank and would burn away therefore topping up was frequent. The drawbacks of this engine in comparison to those of Daimler were that they were heavier and ran at less than half the speed. This car was introduced to the public in 1887 however the year before Daimler had introduced a four-wheeled vehicle with a vertically opposed engine producing 1 ½ hp, and it was this engine that would live on into the following century.

Subsequently, Daimler approached lawyer Edouard Sarazin who was well-known in his day for handling claims from numerous inventors all claiming name to these innovations. Sarazin, who held the French patent on Daimler’s engine, introduced it to Emile Levassor (1843-1897) and Rene Panhard (1841-1908) who agreed to build the engines in France providing they not be assembled using imported parts from Gottlieb Daimler. The first model was built in 1890 using a centrally mounted engine with another front-engined model being introduced the following year so that it would not be subject to road debris being thrown up from the roads of the late 19th century which would have been little more than dirt tracks.

The mechanical layout of this car would then dominate the motor car industry for many years to come. Levassor would then go on to introduce other aspects to the motor vehicle as we know it such as scrapping belt transmission in favour of a clutch and gearbox, the front-engine rear-drive arrangement and the gilled-tube radiator. By the turn of the century the motor car had its own unique identity and was being built all over Europe and the United States of America.

During the early days of motoring, a law was laid down, known as the “red flag law” in which propelled vehicles would be restricted to a speed limit of 4 mph across the country and 2 mph in built up areas with a man who would walk 60 yards in front of the car carrying a red flag. This law was abolished in 1878 however, somebody was still required by law to walk a minimum of 20 yards in front of the car, assisting horse drawn carriages as necessary until 1896.

In celebration of this abolition, an emancipation run from London to Brighton took place, in which red cloth was torn up and speeds of up to 14 mph were reached!. It was this run which would go on to inspire the London to Brighton veteran car run today. Since these early days of the motor vehicle, it has gradually evolved into the motor vehicles of today that many of us have became accustomed to.

|

| 1885 Benz patent. One of the first motor cars ever built |

|

| Detail showing the unique engine layout of the 1885 Benz |